VENEER OPTIONS

Specifying Face and Back Veneers

Many factors determine the appearance and cost of decorative veneers used in States hardwood plywood panels. Face and back veneers are available in a wide variety of species, colors, grades and other attributes. Being able to choose exactly the right combination to achieve the desired appearance is part of what makes hardwood plywood such a popular choice for designers, architects, craftsmen and other woodworking professionals.

Four Factors

When designing your custom States hardwood plywood panel, you can get as specific as you want about the characteristics of the veneers used on your project. There are four key attributes that determine the appearance and cost of the veneers for your decorative wood panel:

Wood Species

Primary determinant of color and grain

Veneer Cutting

Determines how the grain is presented

Veneer Matching

Arranging veneer leaves to create specific patterns

Grade

Indicates quality and natural variation

Did you know?

A “flitch” is a complete bundle of thin sheets of veneer after cutting, laid together in sequence as they were sliced or sawn.

Wood Species

Wood species is the primary determinant of the color and grain structure of veneers. Generally, wood species are divided into hardwoods (deciduous or leaf bearing) and softwoods (coniferous or cone bearing). In addition, wood species are often classified as open grain or closed grain, which refers to the texture of the wood’s cell structure.

Popular Hardwood Species

Maple

Birch

Oak

Cherry

Popular Softwood Decorative Face Veneers

Cedar

Pine

Redwood

Fir

States offers a virtually unlimited selection of veneer species.

Contact us for details and options.

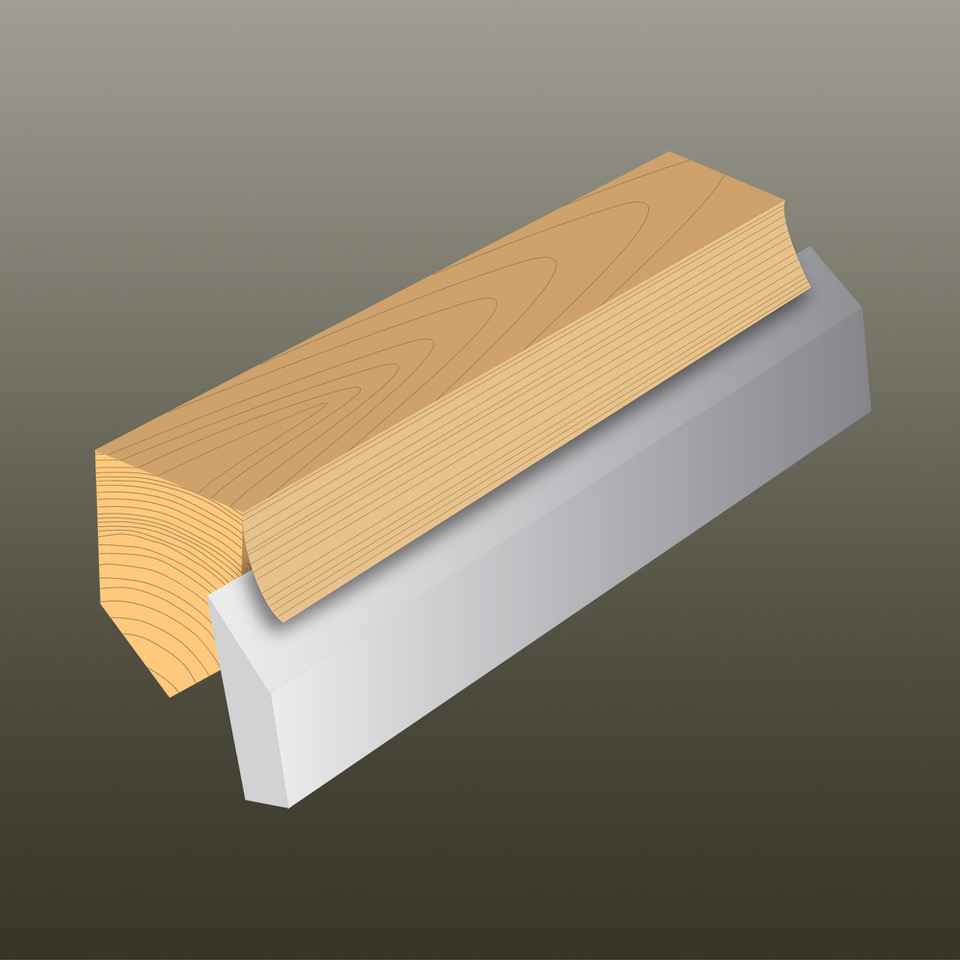

Veneer Cutting Methods

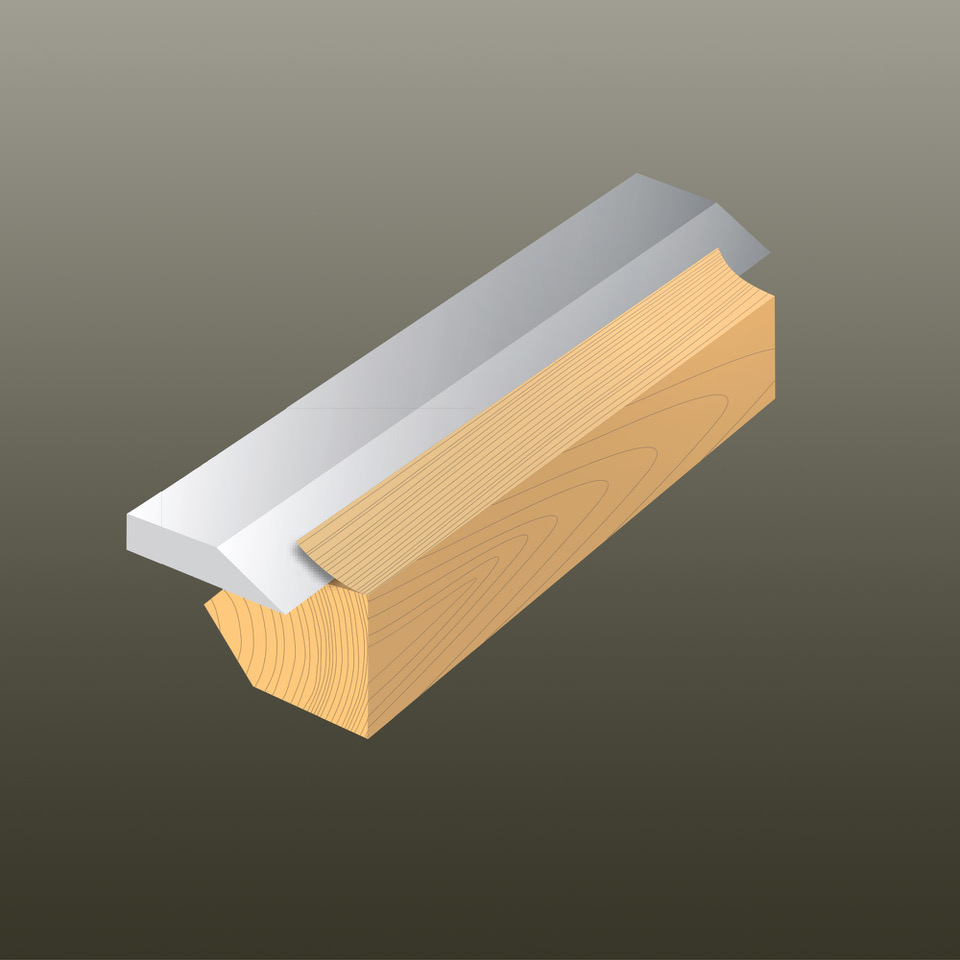

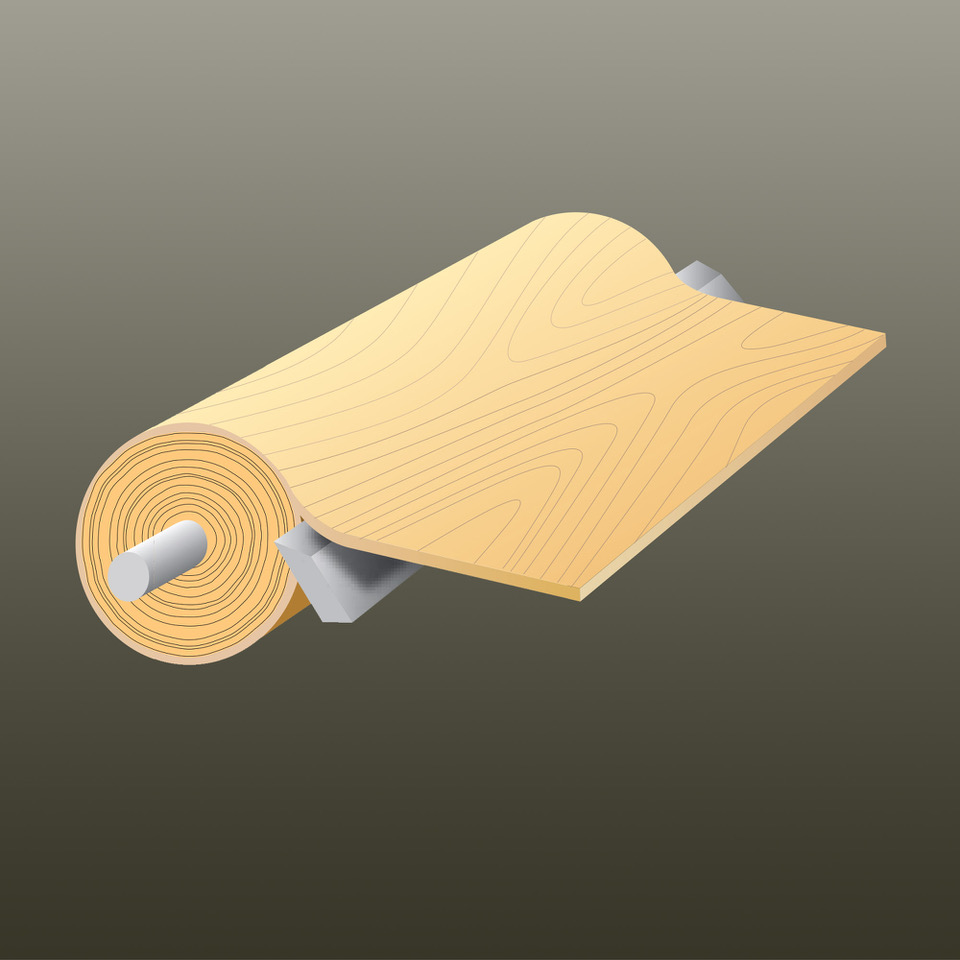

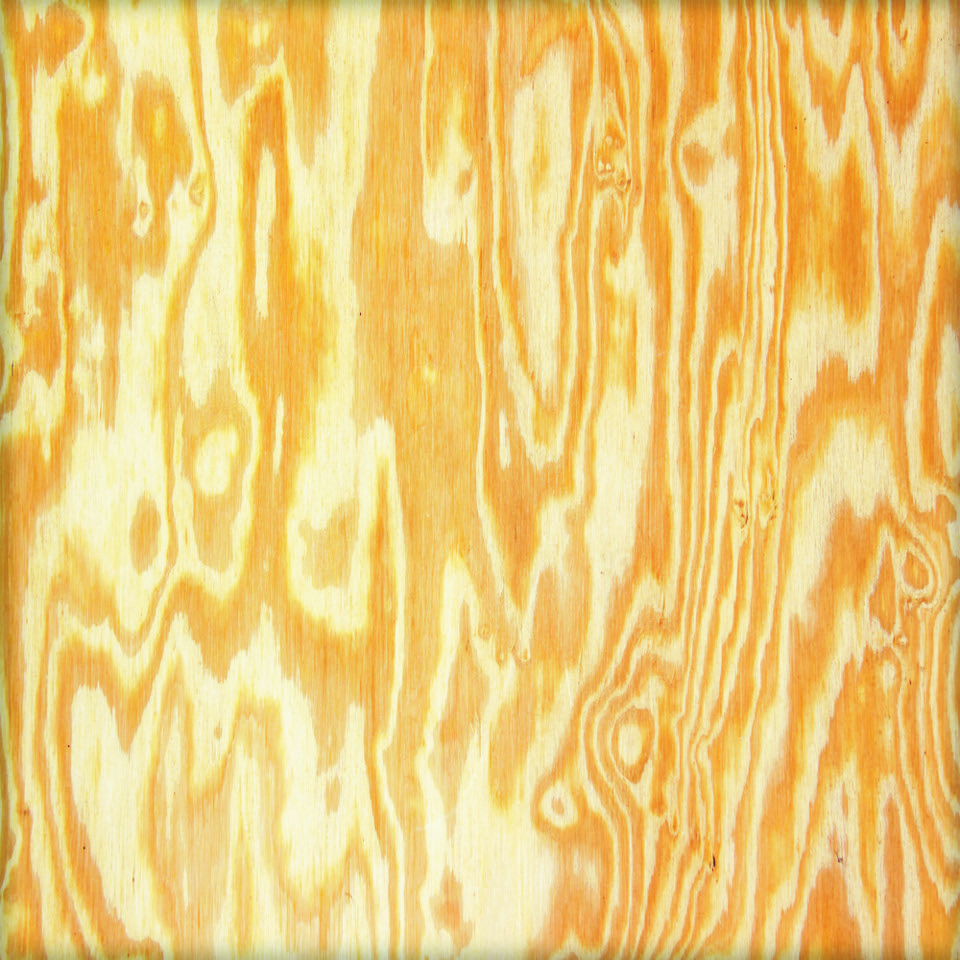

Rotary Cut

Veneers are peeled from a log like paper coming off a roll. This method produces large pieces of veneer with flat, random grain patterns. This is generally the least expensive cutting method, but rotary veneers can have a bland appearance and may vary widely in pattern or color.

Ideal for:

- Projects where a low price point is more important than a consistent appearance

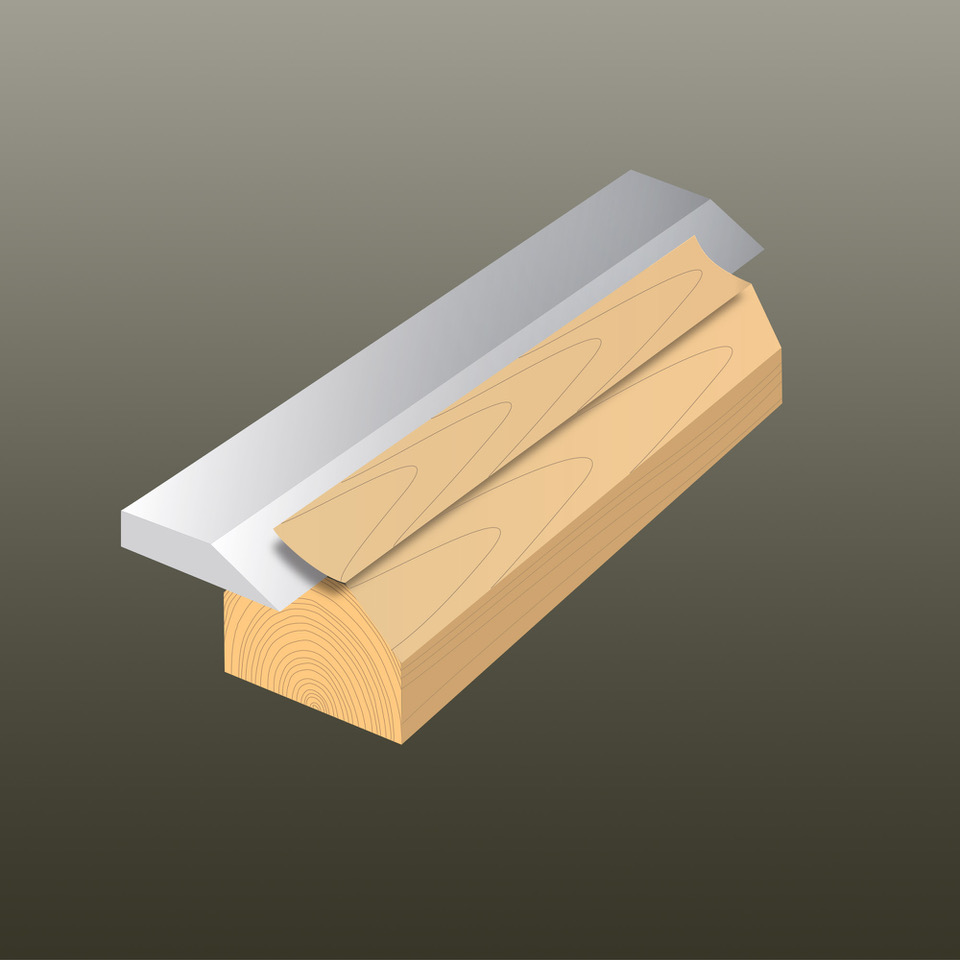

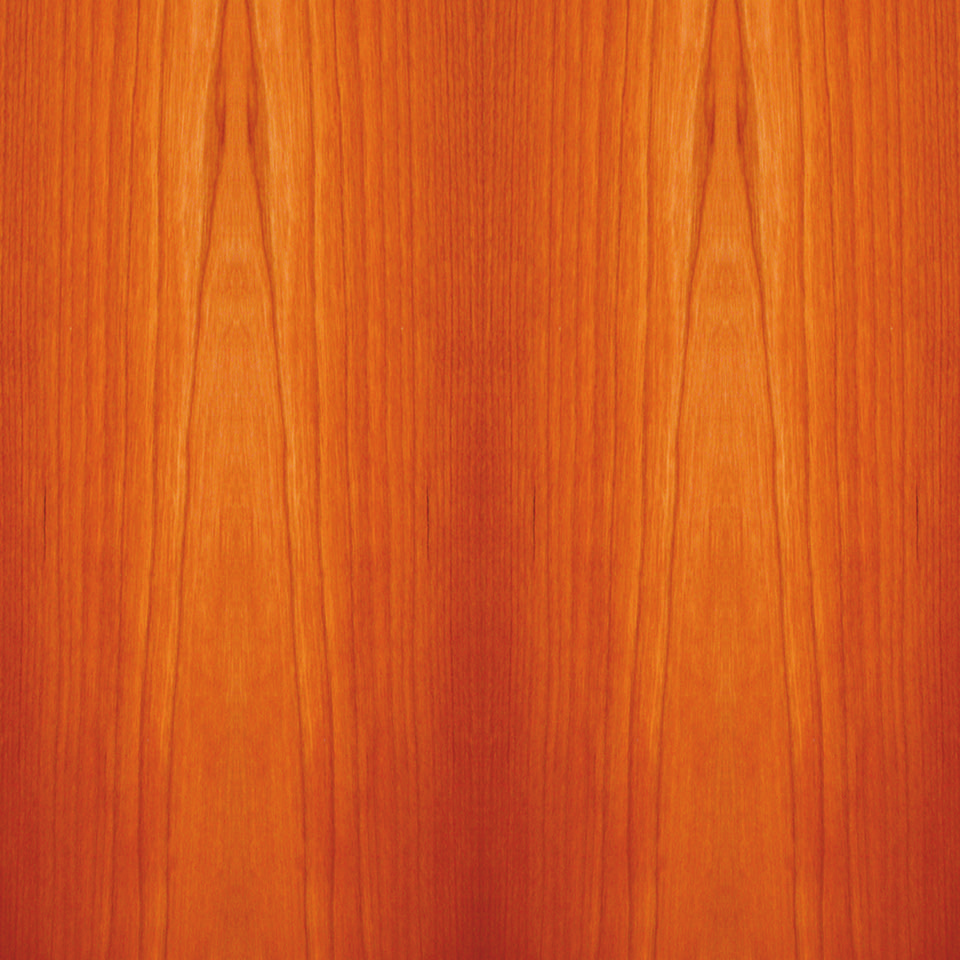

Plain Sliced

Veneers are cut along a log’s growth rings and typically present a cathedral grain pattern with veneer leaves that are 6 to 12 inches wide. Plain Slicing is the most common, as it produces the highest yield and is generally the least expensive slicing method.

Ideal for:

- Wall panels

- Doors

- Furniture

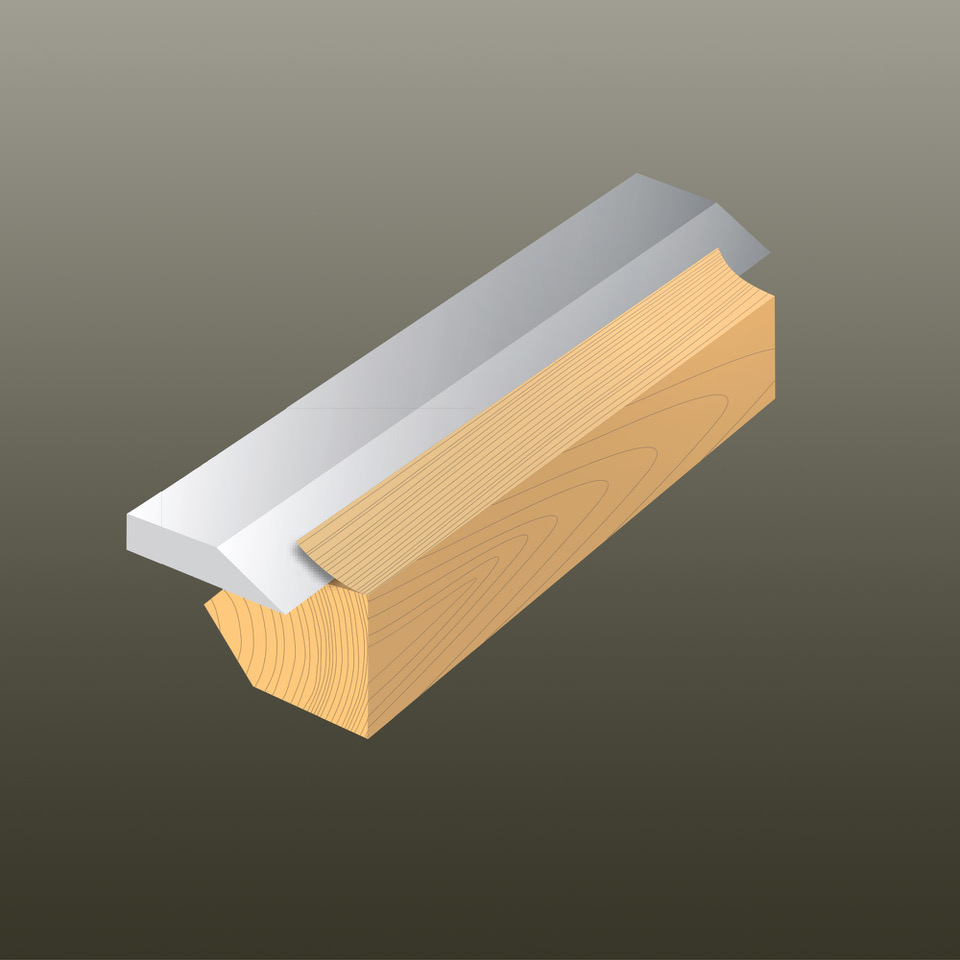

Quarter Sliced

Veneers are cut perpendicular to a log’s growth rings and generally produce a very straight grain. Veneer leaves are cut consecutively and are easy to match. In many species this method will reveal a decorative element in the wood, like flake patterns in white oak. Quarter slicing produces smaller veneer leaves and is more expensive.

Ideal for:

- Cabinetry

- Flooring

- High-end custom crafts and furniture

Rift Cut

Veneers are sliced at an angle of 15 degrees to the radius of the log. This method is most often used for oak. It is intended to produce a straight grain and minimize the oak’s ray flake effect. Rift slicing is the most expensive because it results in the most waste. It is easily sequenced and matched.

Ideal for:

- Fine furniture

- Projects that require a consistent, long, straight grain

Veneer Matching

Other than rotary cut whole piece faces, all veneers for full-sized panels must be assembled into large sheets or “spliced” together. How the veneer leaves are arranged is called veneer matching and will produce a specific pattern in the finished panel. Veneer matching should not be confused with panel matching which refers to the relationship between several panels in a sequence, as in a large auditorium.

Different matching techniques are used for specific panel applications.

Pleasing Match

Veneers are selected for uniformity of color without regard to grain pattern. No sharp color contrast is allowed, but grain patterns may not match.

Book Match

This is the most common matching method in which alternating leaves of veneer are turned over like the pages of a book. The result is a pleasing symmetrical pattern of mirror images of grain.

Slip Match

Adjoining veneer leaves are fed out in sequence without being turned so that the same side of the veneer leaves is exposed. This allows the grain pattern of the leaves to repeat across the face of the panel, improving color uniformity.

Random Match

Veneer leaves are assembled without regard to grain pattern or color. Visual continuity is not guaranteed, though some species are naturally more uniform than others.

Whole Piece

One single piece of veneer is used with continuous grain characteristics running across the sheet.

Veneer Grading

Veneer Grading is based primarily upon the appearance of the finished product. States grades its veneer based on the standards outlined by the Decorative Hardwoods Association (formerly the Hardwood Plywood and Veneer Association).

Face Grades

AA

A premium face grade for exclusive uses such as architectural paneling and interiors, case goods and quality furniture.

A

Where AA is not required, but excellent appearance is still important.

B

Where the natural characteristics and appearance of the species are desirable.

C

Allows for unlimited color and increased natural characteristics. Perfect for applications where an economical panel is needed.

D & E

Provide sound surfaces but allow unlimited color variation and repairs in increasing size ranges. For use in applications where the surface will be hidden or a more rustic character is desired.

Back Grades

Back Grades are designated by numbers 1, 2, 3 and 4. Requirements of Grade 1 are most restrictive, with Grades 2, 3 and 4 being progressively less restrictive. Grades 1 and 2 provide sound surfaces with all openings in the veneer repaired except for vertical worm holes not larger than 1.6 mm (1/16″). Grades 3 and 4 permit some open defects; however, Grade 3 can be obtained with repaired splits, joints, bark pockets, laps and knotholes to achieve a sound surface if specified by the buyer. Grade 4 permits knot holes up to 102 mm (4″) in diameter and open splits and joints limited by width and length.