COMPARE CORES

Choose Your Substrate

When you order hardwood plywood from States Industries, you can choose the type of core or “substrate” used in assembling your panel products. The substrate is the base material over which thin decorative face and back veneers are applied. Core selection is often a balance between performance characteristics and price.

Three Common Types of Cores

Core Types

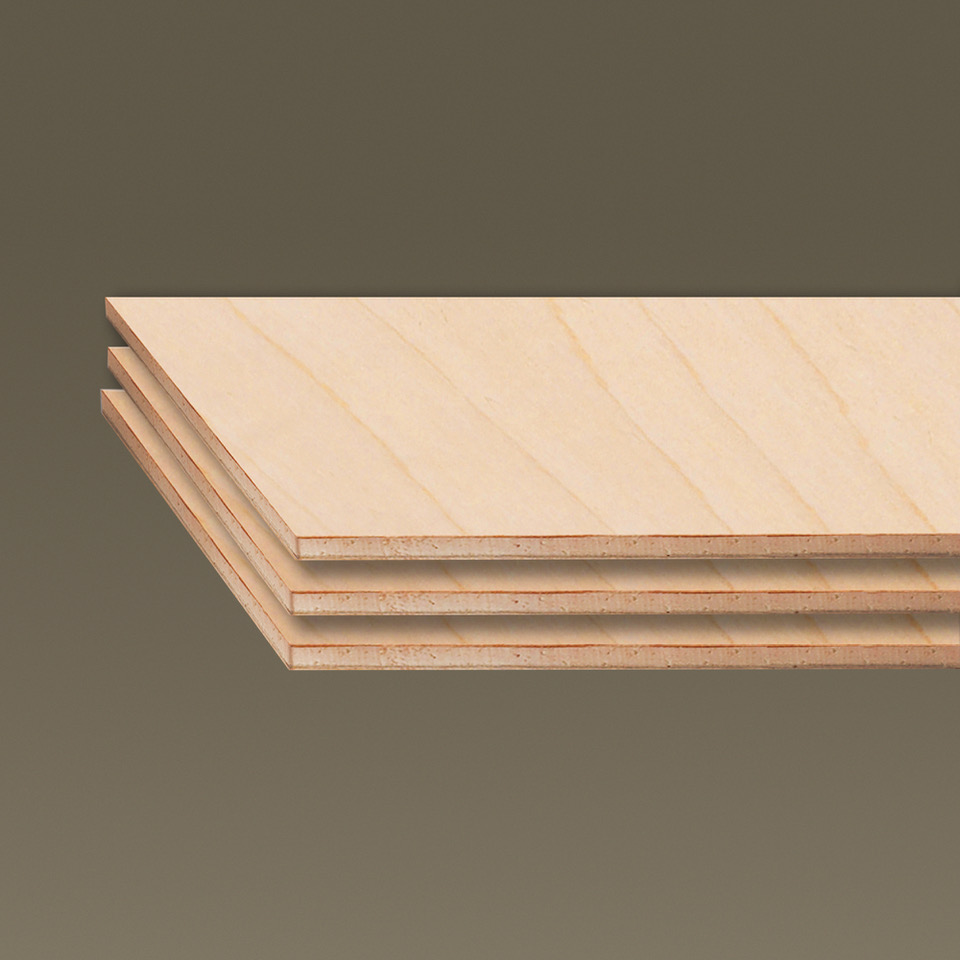

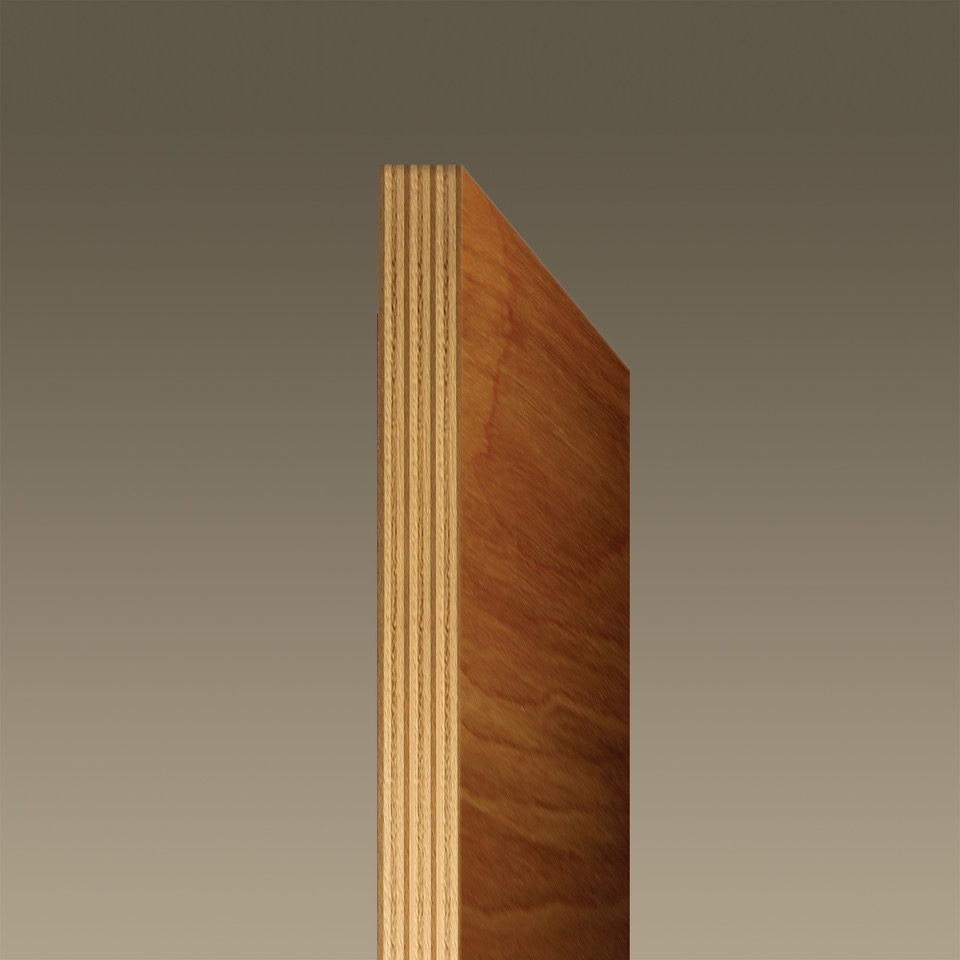

Veneer Core

Veneer core is comprised of wood veneers laminated in alternating directions to achieve the desired panel thickness. Generally, the higher number of plies used, the better the core. Veneer core panels are lightweight and hold screws better than most other substrates. They are also high in dimensional stability and bending strength. Veneer core panels may be laminated in one step for maximum economy or constructed and sanded to a metered tolerance using a two-step laminating process.

Attributes of 2-Step Veneer Core

Flatness

Visual Edge

Surface Uniformity

Dimensional Stability

Screw Hiding

Bending Strength

Thickness Tolerance

Cost

ApplePly®: Premium Hardwood Panels

ApplePly is States’ highest quality, veneer core panel, constructed from 1/16” Birch using a two-step lamination process. Because the innerplies are thin, uniform hardwood veneers, ApplePly machines beautifully. ApplePly is specified for its attractive edge, high strength and solid hardwood core. It is widely used in retail fixtures, contemporary furniture and architectural interiors, where its attractive edge is incorporated as a design element.

Attributes of ApplePly

FLATNESS

VISUAL EDGE

SURFACE UNIFORMITY

DIMENSIONAL STABILITY

SCREW HIDING

BENDING STRENGTH

THICKNESS TOLERANCE

Cost

ArmorCore®: Combination Core

ArmorCore is a hybrid substrate, combining composite crossbands with veneer innerplies to produce an exceptionally flat, smooth surface. ArmorCore is preferred in applications where panels need to have the weight, structural value and screw-holding ability of veneer core with the superior flatness and higher density of MDF. ArmorCore is offered in one-step and two-step construction for maximum flexibility.

Attributes of 2-Step ArmorCore

FLATNESS

VISUAL EDGE

SURFACE UNIFORMITY

DIMENSIONAL STABILITY

SCREW HIDING

BENDING STRENGTH

THICKNESS TOLERANCE

Cost

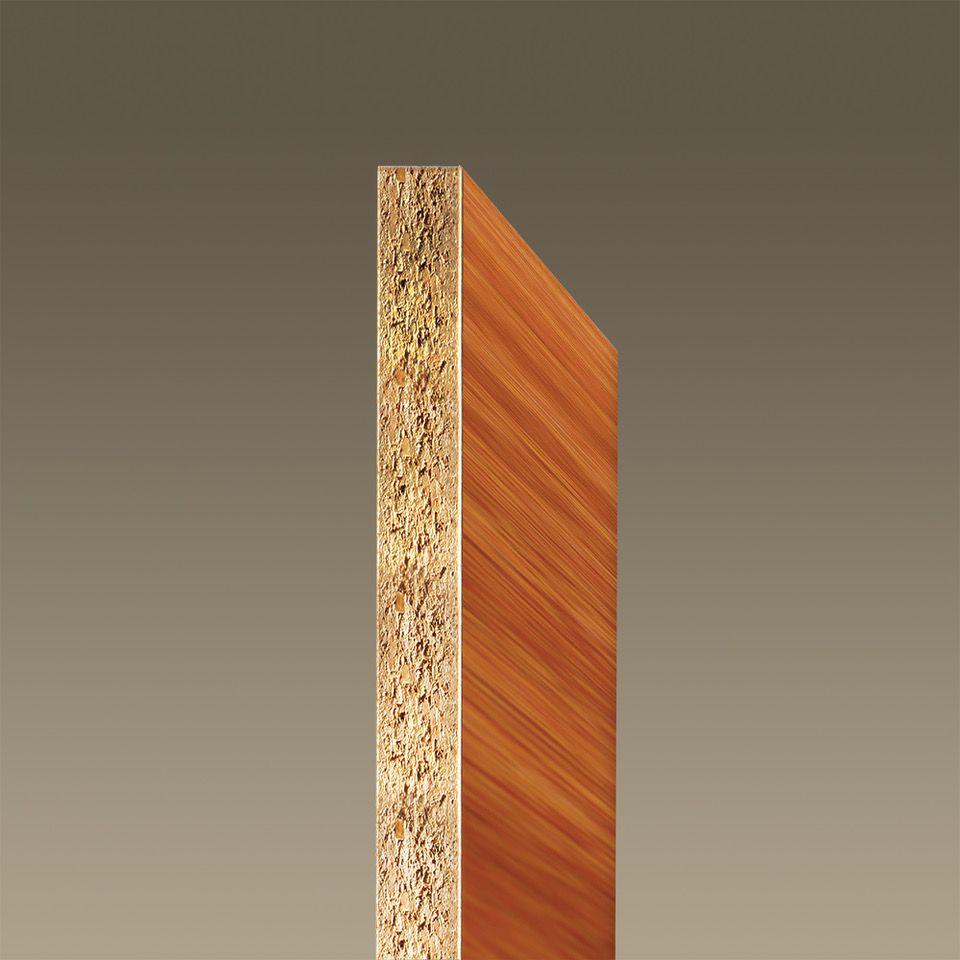

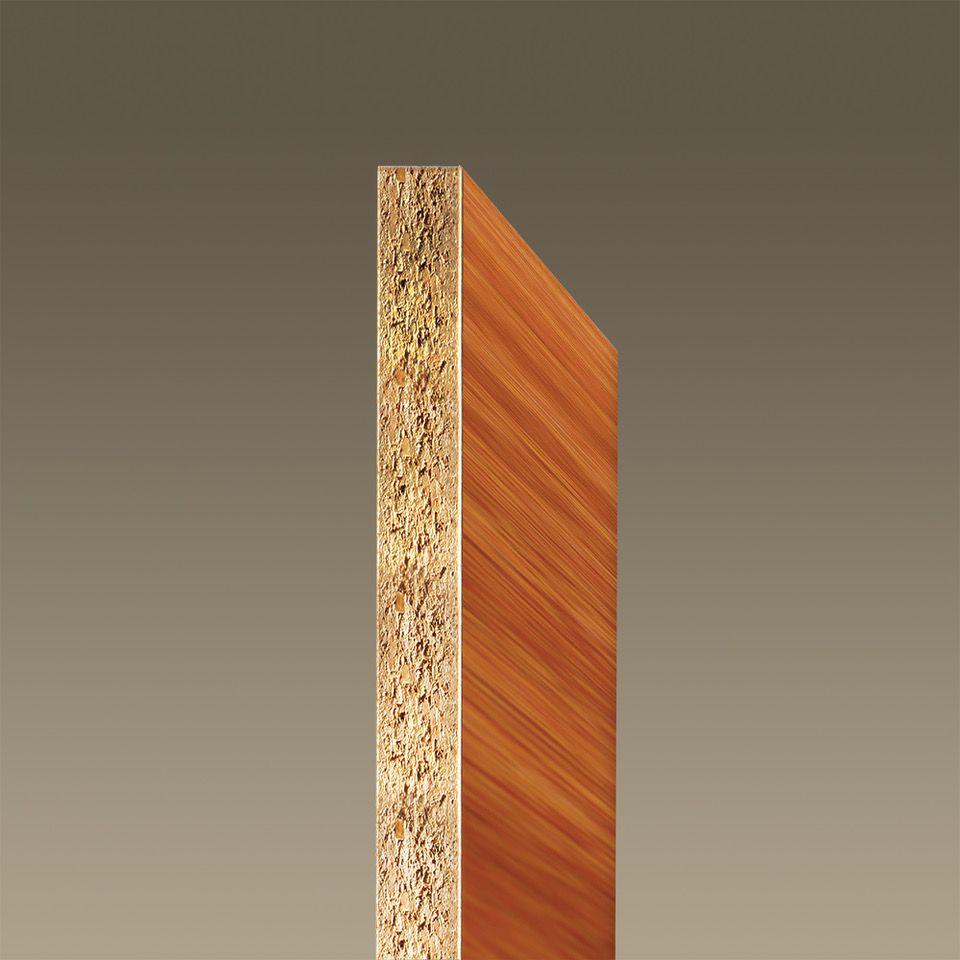

Composite Core

Composite core panels include particleboard and MDF of several densities. Composite cores are valued for their flat, smooth surfaces and tight tolerances, as well as their relatively low costs. MDF is available in both thin and thick versions, and its more refined particles improve its machinability. Particleboard is available in thicknesses above 7/16” and is the lowest cost substrate used in hardwood plywood.

Attributes of MDF

FLATNESS

VISUAL EDGE

SURFACE UNIFORMITY

DIMENSIONAL STABILITY

SCREW HIDING

BENDING STRENGTH

THICKNESS TOLERANCE

Cost

One-step vs Two-step construction

In conventional one-step hardwood plywood layup, all veneers—including the face and back—are laminated at one time. Two-step layup means that the inner plies are first laminated into a “blank” and any surface knots or splits are puttied. The blank is then sanded to a calibrated tolerance and overlaid with face and back veneers. The advantages of using the more expensive two-step construction are the smoothness of the surface and the consistency of the panel’s thickness.

Compare Core Attributes

Flatness

1-Step Veneer

2-Step Veneer

ApplePly

1-Step Armorcore

2-Step Armorcore

MDF

Particleboard

Visual Edge

1-Step Veneer

2-Step Veneer

ApplePly

1-Step Armorcore

2-Step Armorcore

MDF

Particleboard

Surface Uniformity

1-Step Veneer

2-Step Veneer

ApplePly

1-Step Armorcore

2-Step Armorcore

MDF

Particleboard

Dimensional Stability

1-Step Veneer

2-Step Veneer

ApplePly

1-Step Armorcore

2-Step Armorcore

MDF

Particleboard

Screw Hiding

1-Step Veneer

2-Step Veneer

ApplePly

1-Step Armorcore

2-Step Armorcore

MDF

Particleboard

Bending Strength

1-Step Veneer

2-Step Veneer

ApplePly

1-Step Armorcore

2-Step Armorcore

MDF

Particleboard

Thickness Tolerance

1-Step Veneer

2-Step Veneer

ApplePly

1-Step Armorcore

2-Step Armorcore

MDF

Particleboard

Cost

1-Step Veneer

2-Step Veneer

ApplePly

1-Step Armorcore

2-Step Armorcore

MDF

Particleboard

How Innerplies Impact Panel Quality

Number of plies

Generally, the more plies used in a panel of the same thickness means that the volume of open knots in each layer of veneer is reduced because the veneers are thinner. In laminating, the adjoining veneers will compress somewhat into any voids, further minimizing their impact on the panel.

Species and grade

The strength, color, machinability and level of defect in a finished panel directly reflect the species and grade of the innerply material. Higher grade and lighter color crossbands, such as Lauan or hardwood, are options that can be specified for the layers directly under the face and back veneers.